Quantum Motion, a UK-based quantum computing company, has successfully measured 1024 quantum dots on a chip in 12 minutes at tens of milliKelvins (-273 degrees Celsius), which are necessary for the spin qubits to function with the lowest possible error rate. Their achievement paves the way for mass-producing quantum chips using conventional silicon manufacturing processes.

Transitioning from small-scale quantum processor demonstrations to large-scale quantum computers is a significant challenge in quantum computing technology. An example is addressing each qubit in a large array without requiring a significant number of input/output connections to the chip. Quantum chips must be managed in the same way that conventional CPUs are, with billions of transistors but just a few hundred input/output connections to a motherboard.

To do this, not only must quantum devices be manufactured using the same techniques as traditional electronics, but the electronics circuits must also be designed to work at the ultralow temperatures necessary for qubit functioning. With Bloomsbury, Quantum Motion ticked the boxes and achieved significant acceleration in the measurement and validation of silicon-based quantum circuits.

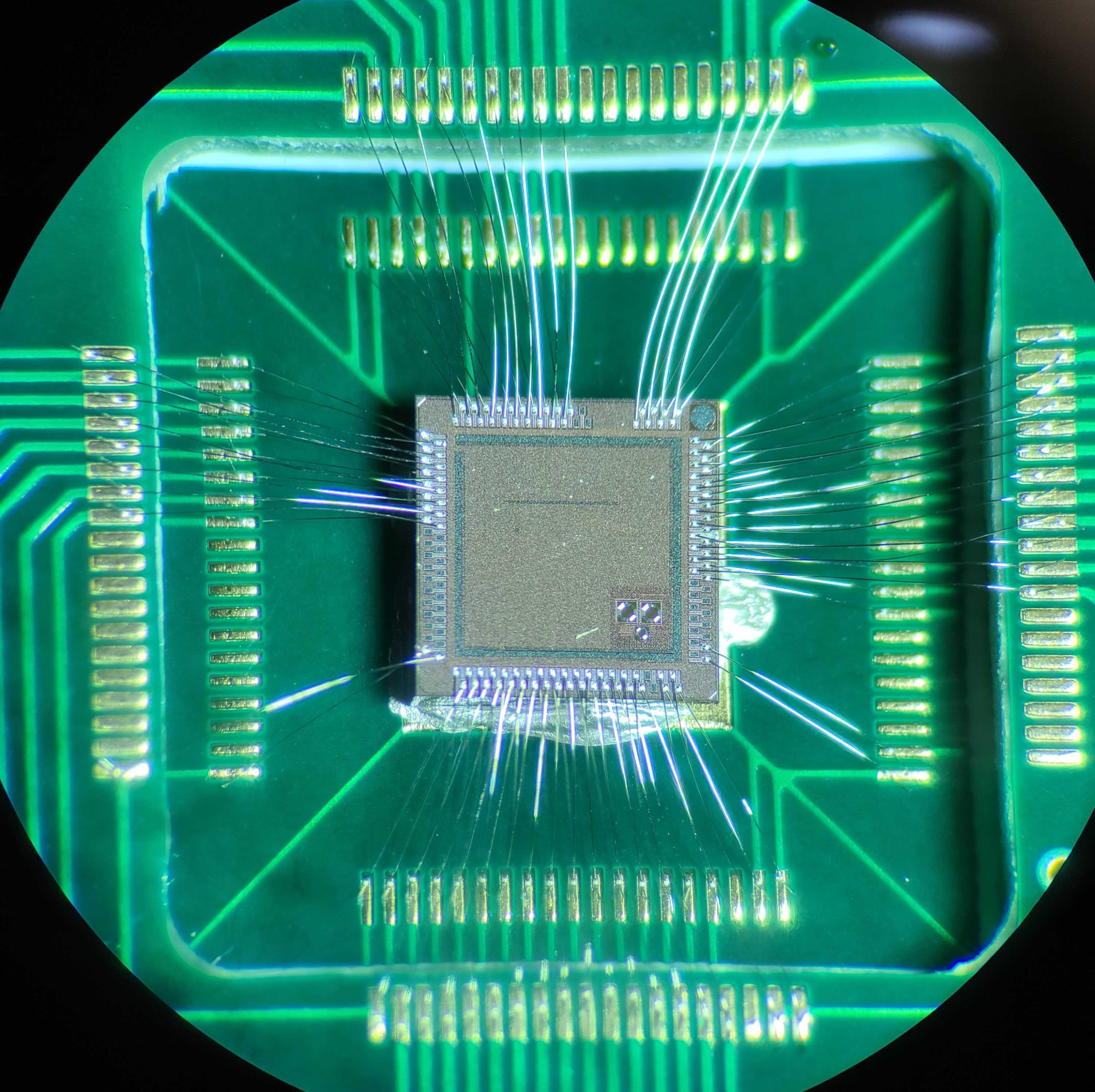

Bloomsbury, the newest chip from Quantum Motion, is a 33mm² device occupying an area of less than 0.1mm². It was manufactured with the 300mm wafer fabrication methods suitable for high yield and high volume chip production. It comprised thousands of quantum dot devices placed alongside control electronics that operate at temperatures less than one-tenth of a degree above absolute zero.

The name Bloomsbury stems from Quantum Motion’s Bloomsbury headquarters, which collaborated closely with UCL’s cryogenic laboratory facilities until its independent lab in London opened.

“What our IC validation team brings to the table is experience in high-volume testing. In a production environment or other traditional electronics testing, test time is one of the biggest manufacturing costs for a company that is trying to produce high-volume products. Our team has knowledge of test time reduction techniques that helps us minimize the time it takes to test a large quantity of devices.”

Grayson Noah, the Senior IC Validation Engineer at Quantum Motion