Researchers at Columbia Engineering’s Gaeta Lab have developed a technique to modify the nanostructure of 2D materials using lasers. The team, led by PhD student Cecilia Chen, used commercially available lasers to create tiny nanostructures in a material called hexagonal boron nitride. The technique doesn’t require a cleanroom or expensive equipment. The team found that their laser-cut samples could create and capture quasiparticles called phonon-polaritons, which could be key to miniaturizing optical devices. The technique can create many customizable nanopatterns, offering researchers a simple way to modify materials with light.

Laser-Induced Nanopatterning of 2D Materials

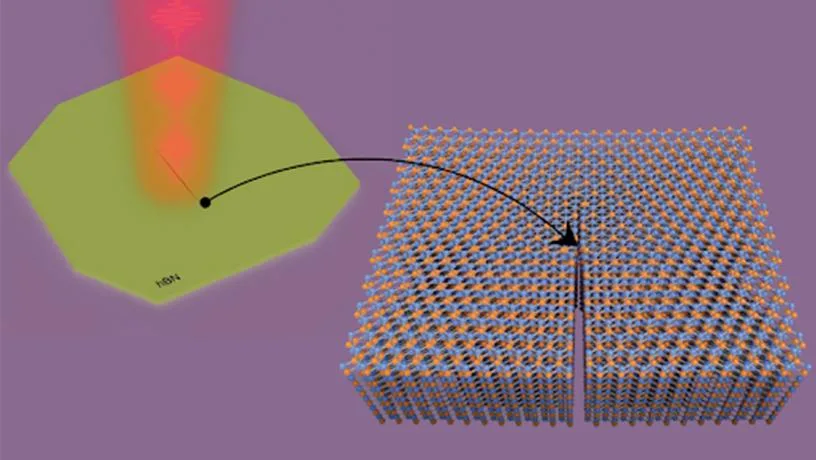

In a recent study published in Science Advances, a team of researchers at Columbia Engineering demonstrated a novel technique for creating nanopatterns in a 2D material known as hexagonal boron nitride (hBN). The method, which involves the use of commercially available tabletop lasers, allows for the creation of atomically sharp nanostructures without the need for a cleanroom or expensive etching equipment.

The team discovered that their laser-cut hBN samples could generate and capture quasiparticles known as phonon-polaritons, which are produced when atomic vibrations in a material combine with photons of light. This finding has significant implications for material development, as nanopatterning is a crucial component of turning materials with interesting properties into functional devices.

The Paradox of Optical Driving

The technique developed by the Columbia Engineering team, led by Professor Alexander Gaeta, leverages a concept known as “optical driving.” This involves enhancing the natural vibrations of a material by tuning lasers to its resonant frequency. In the case of hBN, this frequency corresponds to a wavelength of 7.3 micrometers.

Interestingly, the team found that they could create very sharp nanostructures using very long wavelengths, a phenomenon that contradicts conventional wisdom. Typically, shorter wavelengths are required to create smaller patterns. However, the team’s technique allowed them to create lines across the sample that were atomically sharp and much smaller than the mid-infrared laser wavelengths used to create them.

Exploring the Potential of Phonon-Polaritons

In collaboration with physicist Dmitri Basov’s lab, the engineering team explored the potential applications of their nanopatterned samples. They found that the laser-cut lines provided favorable conditions for creating phonon-polaritons, quasiparticles that can help scientists detect features in a material that give rise to quantum phenomena.

These quasiparticles could also be a key component in the miniaturization of optical devices, a process that has been challenging compared to the miniaturization of electronic devices. The team found that their technique could create nanostructures anywhere on a sample, offering a wide range of options for modifying hBN and exploring how its nanopatterning can influence its resulting properties.

Customizable Nanopatterns and Clean Room Independence

The laser-induced nanopatterning technique can create a variety of customizable nanopatterns. It can create any number of parallel lines, and the spacings between these lines can be adjusted as desired. This flexibility could significantly enhance the imaging ability of phonon-polaritons.

Moreover, the technique does not require a clean room, which is a significant advantage over other nanopatterning methods. The team has successfully unzipped samples as thick as 80 nanometers and as thin as 24 nanometers, suggesting that the technique could be used to modify a wide range of materials.

Future Directions and Potential Applications

While the team’s technique has shown promise, there is still room for improvement. For instance, the technique currently only produces straight or angled lines meeting at either 60° or 120°. However, the team believes that it should be possible to combine these lines into triangles.

Additionally, the breaks can only occur in-plane at the moment. If the team can figure out how to target out-of-plane vibrations, they could potentially shape a bulk crystal into different three-dimensional shapes. Despite these limitations, the team is excited about the potential applications of their technique, particularly in the field of 2D materials.

External Link: Click Here For More