Researchers from EPFL’s School of Engineering have developed a new processor that integrates data processing and storage, reducing energy consumption. The in-memory processor, the first of its kind based on a two-dimensional semiconductor material, comprises over 1000 transistors. The team, led by Andras Kis, used molybdenum disulfide (MoS2) to create the processor. The research, published in Nature Electronics, could lead to significant energy savings in the ICT sector. The development also highlights the potential for non-von Neumann processing architectures, which could revitalise European chip manufacturing.

Energy Efficiency in Data Processing

Information and communication technologies (ICT) convert electricity into heat as they process data. The global ICT ecosystem’s carbon footprint is comparable to that of the aviation industry. A significant portion of the energy consumed by computer processors is not used for performing calculations but is spent transferring data from the memory to the processor.

Researchers from the School of Engineering at EPFL’s Laboratory of Nanoscale Electronics and Structures (LANES) have developed a new processor that addresses this inefficiency. This processor, known as an in-memory processor, integrates data processing and storage onto a single device. The researchers have created the first in-memory processor based on a two-dimensional semiconductor material with more than 1000 transistors, a significant step towards industrial production.

“Today, there are ongoing efforts to merge storage and processing into a more universal in-memory processors that contain elements which work both as a memory and as a transistor,”

Andras Kis

The Legacy of Von Neuman Architecture

The inefficiency of current CPUs is largely due to the universally adopted von Neuman architecture. This architecture physically separates the components used for calculations and data storage. As a result, processors need to retrieve data from the memory to perform calculations, which involves moving electrical charges, charging and discharging capacitors, and transmitting currents along lines – all of which dissipate energy.

Until about 20 years ago, this architecture was practical as different devices were needed for data storage and processing. However, the von Neuman architecture is increasingly being challenged by more efficient alternatives. Current efforts are focused on merging storage and processing into universal in-memory processors that contain elements functioning both as memory and as a transistor.

A New Two-Dimensional Processor Architecture

The researchers have developed an in-memory processor based on molybdenum disulfide (MoS2), a semiconductor material. This processor is dedicated to one of the fundamental operations in data processing: vector-matrix multiplication. This operation is prevalent in digital signal processing and the implementation of artificial intelligence models. Improvements in its efficiency could lead to significant energy savings throughout the entire ICT sector.

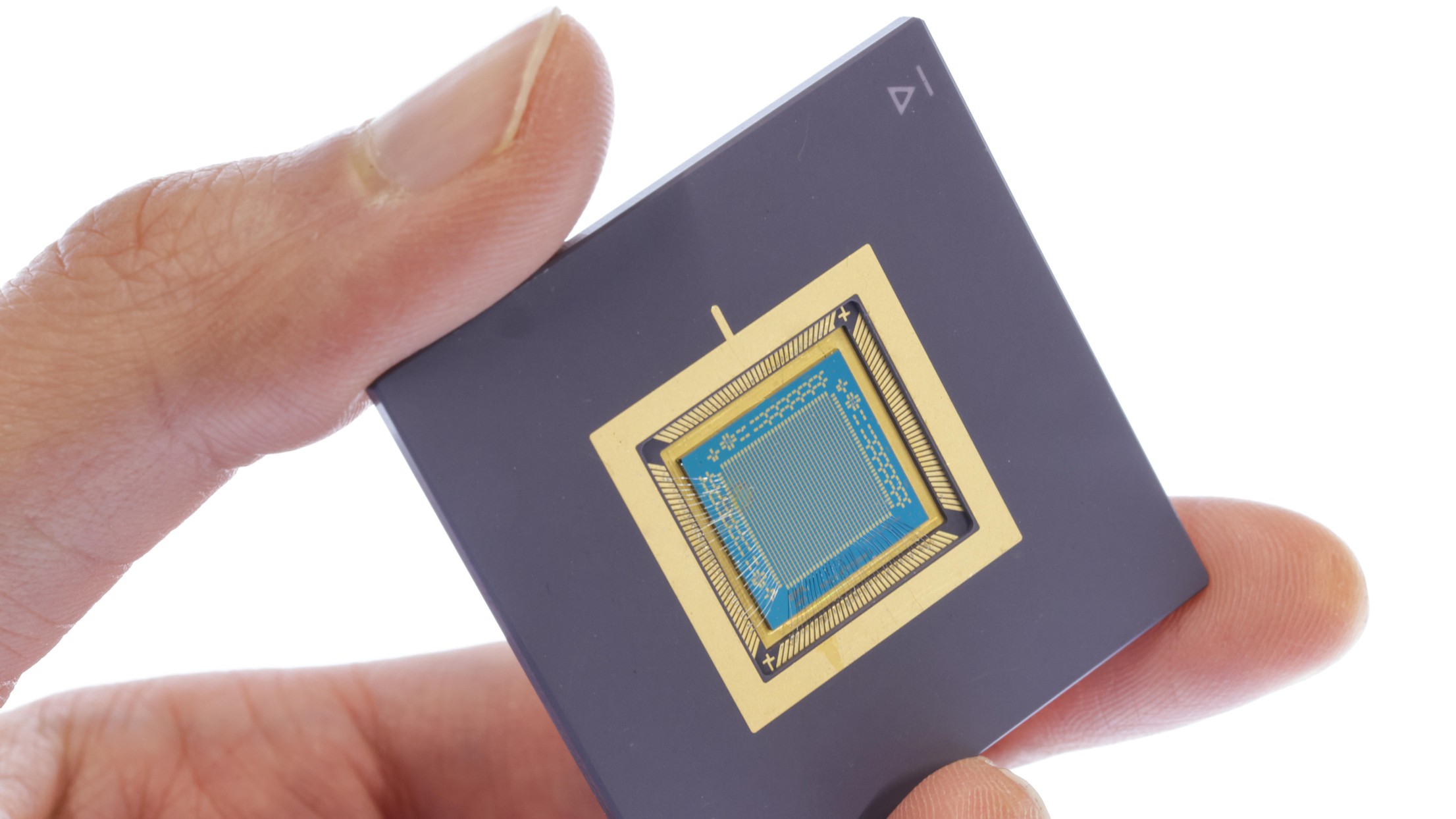

The processor combines 1024 elements onto a one-by-one-centimeter chip. Each element comprises a 2D MoS2 transistor and a floating gate, used to store a charge in its memory that controls the conductivity of each transistor. This coupling of processing and memory fundamentally changes how the processor carries out the calculation.

“The key advance in going from a single transistor to over 1000 was the quality of the material that we can deposit. After a lot of process optimization, we can now produce entire wafers covered with a homogenous layer of uniform MoS 2 . This lets us adopt industry standard tools to design integrated circuits on a computer and translate these designs into physical circuits, opening the door to mass production,”

Andras Kis

The Role of Material Choice in Processor Development

The choice of material – MoS2 – was crucial in the development of the in-memory processor. MoS2 is a semiconductor, a requirement for the development of transistors. Unlike silicon, the most widely used semiconductor in today’s computer processors, MoS2 forms a stable monolayer, just three atoms thick, that only interacts weakly with its surroundings. Its thinness offers the potential to produce extremely compact devices.

“By setting the conductivity of each transistor, we can perform analog vector-matrix multiplication in a single step by applying voltages to our processor and measuring the output,”

Andras Kis

Over the past 13 years, the researchers’ processes have matured substantially. They can now produce entire wafers covered with a homogenous layer of uniform MoS2. This allows them to use industry-standard tools to design integrated circuits on a computer and translate these designs into physical circuits, paving the way for mass production.

The Impact on European Chip Manufacturing

The development of this in-memory processor has implications beyond its scientific value. It highlights the importance of close scientific collaboration between Switzerland and the EU, particularly in the context of the European Chips Act, which aims to enhance Europe’s competitiveness and resilience in semiconductor technologies and applications.

The work carried out in Switzerland could benefit the EU as it seeks to revitalise electronics fabrication. By focusing on developing non-von Neumann processing architectures for AI accelerators and other emerging applications, Europe could secure a strong position in the future.

“EU funding was crucial for both this project and those that preceded it, including the one that financed the work on the first MoS2 transistor, showing just how important it is for Switzerland,”

Andras Kis

Summary

Researchers from EPFL’s School of Engineering have developed a new processor that integrates data processing and storage onto a single device, significantly reducing energy consumption. The processor, based on a two-dimensional semiconductor material called molybdenum disulfide (MoS2), can perform vector-matrix multiplication, a fundamental operation in data processing, in a single step, offering potential for substantial energy savings in the information and communication technologies sector.

- Researchers from EPFL’s School of Engineering in the Laboratory of Nanoscale Electronics and Structures (LANES) have developed a new processor that integrates data processing and storage onto a single device, known as an in-memory processor.

- The team, led by Andras Kis, created the first in-memory processor based on a two-dimensional semiconductor material with over 1000 transistors.

- The inefficiency of current CPUs is due to the von Neumann architecture, which separates the components used for calculations and data storage. This new processor challenges this architecture by merging storage and processing.

- The team used molybdenum disulfide (MoS 2), a semiconductor material, to achieve this goal.

- The processor is dedicated to vector-matrix multiplication, a fundamental operation in data processing. Improvements in its efficiency could lead to significant energy savings in the ICT sector.

- The choice of MoS 2 was crucial for the development of their in-memory processor. Unlike silicon, MoS 2 forms a stable monolayer, just three atoms thick, that only interacts weakly with its surroundings.

- The development of this processor could potentially revitalise European chip manufacturing, as it aligns with the goals of the European Chips Act.

“Rather than running the same race as everyone else, the EU could, for example, focus on developing non-von Neumann processing architectures for AI accelerators and other emerging applications. By defining its own race, the continent could get a head start to secure a strong position in the future,”

Andras Kis